Metal fabrication requires a high degree of efficiency and accuracy. For Melbourne businesses, obtaining a precise cut while working under tight timelines is a challenge faced daily. This is where cutting-edge manufacturing technology comes into play. CNC plasma cutting is an effective solution that is changing how Melbourne workshops work with metal by providing superior accuracy and speed. To improve fabricating abilities, knowing how this technology is processed is where to start.

What is CNC Plasma Cutting?

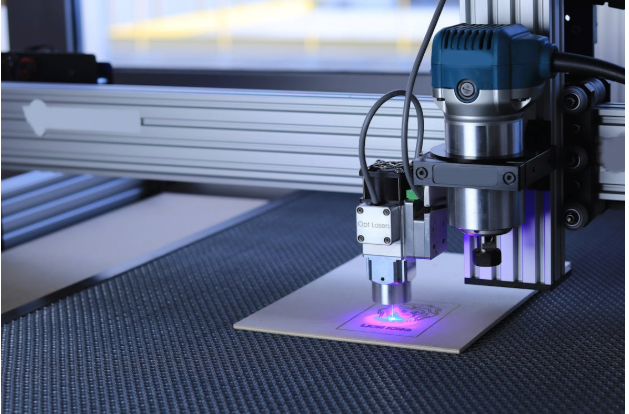

CNC (Computer Numerical Control) plasma cutting is a machine operation that utilises a high-speed flow of ionised gas, or plasma, to cut through electrically conductive metals like stainless steel, aluminium, and steel.

The “CNC” part of this is because it is all computerised. You input a pre-programmed design into the system, which regulates the plasma torch to absolute perfection, so each and every cut is just as intended. This part of automation eliminates human error and allows difficult-to-cut shapes to be created that would be difficult to do manually.

Precision Redefined

The greatest advantage of advanced CNC cutting machines in Melbourne is their incredible accuracy. Standard cutting methods have a hard time producing repeatedly sharp edges and delicate patterns. Meanwhile, a CNC plasma system’s computer-controlled torch draws a clear path, producing smoothly finished high-quality cuts time and time again. This is especially useful when producing a product that must have repeating parts or a highly sophisticated design.

The Role of Automation

The solution is automation. By translating a digital design into direct physical motion, CNC technology ensures that every part is a perfect copy of the last. Consistency is paramount to Melbourne construction and manufacturing markets, where minute changes have a negative effect on product integrity. This results in fewer materials wasted and a higher standard of workmanship.

Improving Efficiency

In a competitive industry, efficiency is no less important than accuracy. CNC plasma cutting serves to seriously accelerate production. While a plasma torch is capable of cutting heavy metals much faster than is possible when using a saw or hand torch, a workshop is able to work on more jobs and meet tighter timelines. Because automation is involved, a machine is able to work with limited supervision so that skilled workers can work on some of those other important jobs such as design and finish.

Streamlining Workflow

Incorporating CNC plasma cutting into a workshop can bring a tangible productivity lift. Transition from a computer-aided design to a finished cut part is made fast, and turnaround time is significantly reduced. For Melbourne companies, it means increased capacity and a competitive edge. Faster production results in a happier customer as well as a healthier bottom line through higher volume production.

The Future of Fabrication

CNC plasma cutting is enabling a spectacular blend of productivity and accuracy that is transforming Melbourne’s metal fabrication business. Automating cutting work is enabling enterprises to enjoy a superior degree of accuracy, less scrap, and rapid lead times. Investing in such machinery is a strategic step for any workshop that seeks to expand its capacity and produce finer results in an increasingly competitive world.